Knob tuning for 2025 Arc

Somewhat late in the production process we worked out a technique for more precise tuning of the amount of friction per knob. Following the procedure below will allow you to reset and adjust friction and wobble across all knobs to get a good match.

Summary:

We’ll reverse the set screw to hit the not-flat side of the D-shaft, while applying pressure from the top of the knob and below the shaft for a tight fit. Then we can back off the tightness to adjust friction and match the knobs.

Tools required:

- small phillips screwdriver

- 0.05” hex wrench (included with arc)

- any appropriate tool to apply pressure to the rear of the encoder shaft (see below)

Process:

- Remove the two bottom screws from the black plate, remove the plate

- Remove all four knobs using the hex wrench

- Back out the set screw for each knob so that you cannot see it in the center mounting hole

- Keep track of the washers. There are either two black plastic washers or several metal washers. (Both work equally well).

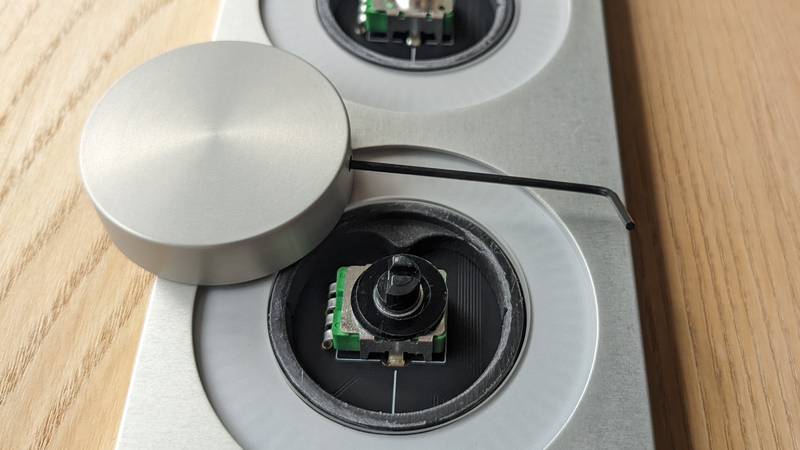

- Align the encoder D-shaft so that the flat part is opposite the set screw, as in the photo below.

- Mount the knob in this position, with the set screw aligned with the opposite side of the D shaft.

- Find the hole in the circuit board which is exactly under the encoder, seen on the left of the photo below. If you peer into this hole you’ll see a small black plastic alignment peg, which we’ll apply pressure to when attaching the knob. We’ll use a tool with a flat top and small enough to fit in the hole. Shown on the right is a 3/32 hex which works well as it has a flat top.

- With the tool inserted from below, apply pressure to the top of the knob and tighten the set screw gently. This might take some experimentation as it’s somewhat a three-handed job. We tend to hold the tool against a table while tightening:

- Attach each knob, tightly enough so the friction barely allows it to move.

- After all four are attached, progressively back off the set screw to dial in the exact amount of friction desired. You’ll be able to match all four by adjusting each set screw.

E-mail help@monome.org if you have any trouble.